How a Mining Company is Using AI to Keep Employees Safe Onsite

Cemin is a copper and gold mining company with two operations in the Valparaíso region of Chile. More than 300 Cemin employees live and work at each location, so COVID-19 posed potentially catastrophic risks. An outbreak among workers could spread fast with major impacts on employee health, mining operations, jobs, and company revenue.

Protecting employees is an important part of the culture at Cemin. In the early days of the pandemic, the company acted quickly to develop a comprehensive system to safeguard employees, including mask wearing and social distancing requirements, health screening questionnaires, and education and training programs. While the company had strong protocols in place, there was no efficient way to monitor compliance, identify problem areas, or track anomalies. It was essential for safety that people followed the guidelines, especially in public spaces such as cafeterias, break rooms, transportation areas, and during work within each of the mines.

The Solution

Lima-based Quipu Consulting, a technical solutions provider specializing in image processing, artificial intelligence, and other next-generation technologies, led the project. Quipu recognized early on how Camio real-time video search and alerting used for tailgating and other security functions could easily help with COVID-19 mitigation regulations and compliance.

Because Camio is a Software-as-a-Service platform that uses existing cameras, it took less than 45 minutes to “light up” cameras at Cemin’s remote mining locations without being on premise. Cemin did not need to purchase any additional hardware and then wait for delivery and installation. Instead, the Camio Box video management runs on its existing VMware ESXi servers.

Camio uses artificial intelligence (AI) and machine learning to turn cameras into sensors capable of detecting the distance between people. It anonymously tracks people as they move on a virtual, three-dimensional floor-plane grid—analyzing movement without storing any personally identifiable information (PII). Measuring distance is safer than taking temperatures since people without fevers can still be contagious with COVID-19. And even when people are six feet apart, Camio automatically detects whether they are wearing masks.

Camio’s real time video search immediately detects areas where COVID-19 mitigation protocols are not being met. Entering simple natural language queries like “too close without mask” into the Camio search box reveals potential problem areas to alert security personnel to take action to address them.

Real-time dashboards also track the rates at which people wear masks and maintain social distance to measure policy effectiveness. Camio Event Streaming pushes only important events directly to the Cemin team, which views alerts on their computers or smartphones. Event stacking then condenses and summarizes contiguous events, so time is not wasted reviewing unimportant or previously acknowledged events.

The Camio system also follows security practices, such as using TLS encryption with Perfect Forward Secrecy and 256-bit AES encrypted storage to meet stringent IT requirements. Remote access is secure with no open in-bound network ports, and Camio operates by isolating the camera network from the corporate network.

The Results

Cemin’s board of directors acted quickly at the beginning of the COVID-19 outbreak, giving the onsite management team one week to implement a system to monitor and report COVID-19 mitigation strategies. Once Cemin selected Camio to provide a solution, Quipu identified cameras in the most critical areas of the mining operation. After several days of analysis and planning, Quipu deployed Camio without ever being on site and provided critical guidance to improve the accuracy of tracking and classification.

Cemin notified employees of its comprehensive COVID-19 mitigation plan, including use of the Camio system, through onsite notifications and posted policies.

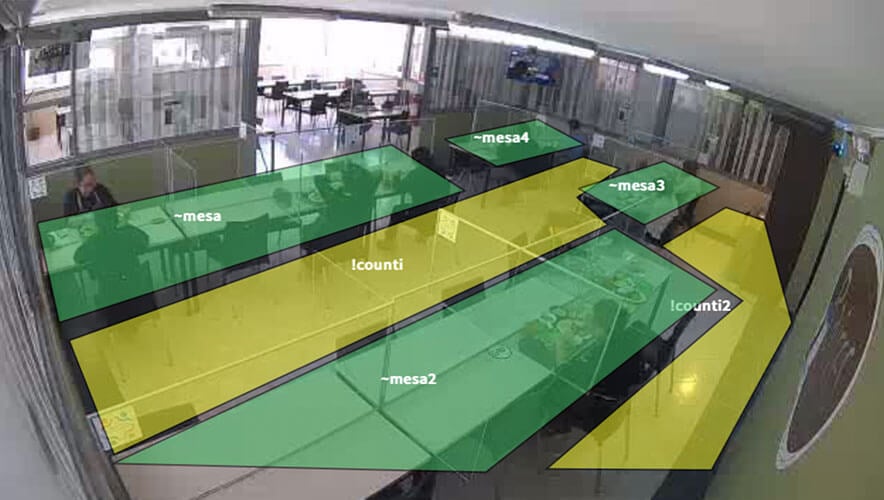

Initially, there were false positive “no mask” detections in dining areas because people took off their masks to eat. Quipu added exclusion zones to cover the transparent plexiglass barriers in those seated dining areas to reduce those false positives. Camio also deployed weekly AI model updates based on examples donated by Quipu to improve accuracy.

Real-time alerts accessible from any browser indicate issues as they happen. Automatic dashboards provide comprehensive insight and enable communication between team members for immediate response. The Cemin team uses dashboard metrics to manage compliance and to report weekly to its corporate board.

“Our board of directors asked for reports on social distancing and mask compliance rates the week before Chilean Independence Day,” says Jose Borroni, Cemin’s chief information technology officer. “Camio made it easy. The automated real-time data and reports even link to the corresponding video events for quick review.”

More than 364,000 events per week are automatically monitored with real-time dashboards for immediate detection and visibility into problem areas. The Cemin team also uses video clips as an educational tool.

“Sharing video with the team was a great way to remind people,” says Marcos Joo, corporate project manager at Cemin. “It’s so easy to forget that something previously so harmless—like sharing a bag of olives—creates risk. Camio’s automated vigilance made it easier for everyone to view mask and social distancing compliance as a shared responsibility.”

Halting operations for even one month across all mines would have cost Cemin more than $4 million. By acting quickly with technology that puts cameras to work to understand the problems that warrant human attention, Cemin was able to sustain operations with no business interruption and protect employee health and well-being. The system also gives peace of mind.

“The Camio system instills confidence in our team that we are keeping people safe while continuing operations,” Borroni says.

The system has worked so well that Cemin, with Quipu’s support, is expanding its use for applications in plants and mines. Cemin plans to train Camio to detect mining equipment and PPE like headlamps, hardhats, and gloves that are required safety equipment onsite.

Cemin is also exploring Camio to evaluate interactions between people and machinery.

“Deploying Camio for COVID-19 mitigation has shown that the same technology can help us identify ways to improve operations and productivity, as well as protect employees,” Borroni says. The software-based platform makes it easy to respond to multiple challenges addressed by AI visual identification and analysis—quickly and economically.

Melanie Crandall is vice president of marketing for Camio. For more information on Camio, contact [email protected] or visit camio.com.